28 Feb THE FUTURE IS NOW | METALWORKING GROUP

The Metalworking Group is currently installing an exciting piece of technology! During the month of November, Mazak Optonics is setting up our new Ytterbium Fiber Optic Laser system for processing sheet metal. The new laser dramatically lowers operating costs with blazing cutting speed that conventional lasers cannot approach.

Ytterbium is quite a mouthful and it is a word that definitely does not garner any recognition, unless you are a chemistry geek and learning the Periodic Table. Ytterbium is listed on the Periodic Table with the symbol Yb. The element was discovered in 1878 by Swiss chemist Jean Charles Galissard de Marignac. For some reason, de Marignac was trying to reduce the rare earth substance, “erbia”, into more finite components. How do people think of doing this stuff!

Ytterbium is used as a dopant in stainless steel to improve strength, to produce gamma rays, and also as an active laser media. We are most interested in the laser application, of course.

The laser wave length produced by Yb allows the laser energy to be delivered by a fiber optic cable. This eliminates all the perishable and expensive mirrors in conventional lasers. The Yb laser consumes 1/3 the electric. The laser beam wave length allows it to cut stainless steel, copper, and aluminum dramatically better than other lasers. And, most importantly, it is fast! It can process 2-3 times faster than regular lasers, or even more, depending on the application.

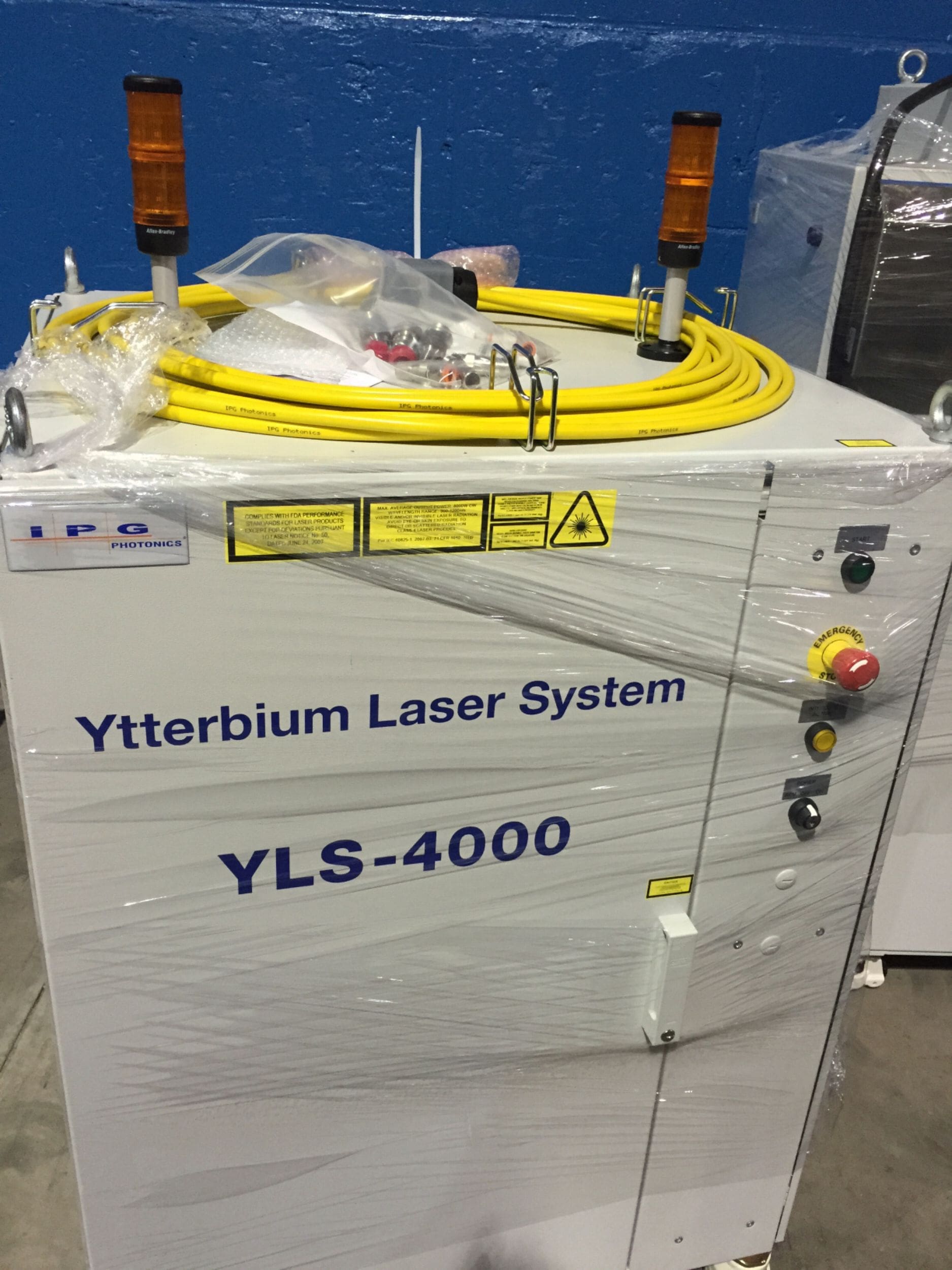

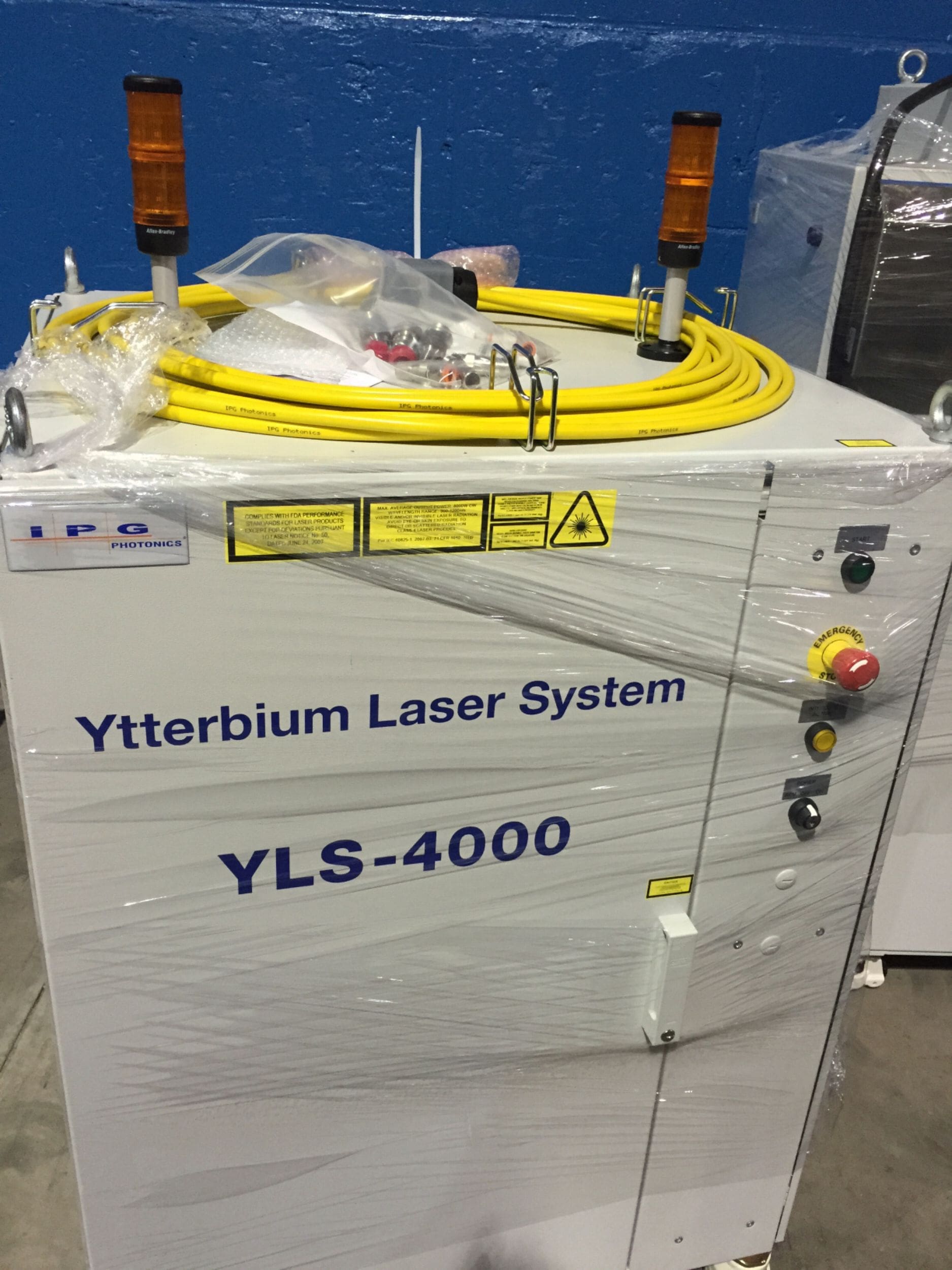

We are excited to bring this fantastic technology to our customers! Pictured below is the Yb laser resonator portion of the machine. It is 20% the size of the old technology, and that yellow fiber optic cord on top is all that is needed to deliver the 4000 watts of laser power.