Precision Metal Manufacturing: Fabrication & Machining Services by MWG

We are a customer-focused, responsive organization that our customers trust to do what it takes to solve their manufacturing challenges. Our collaborative, value-driven, innovative team delivers quality while managing complexity and reducing costs throughout the process.

We continuously invest in upgrading our equipment to expand and support our broad-ranging capabilities.

MWG's Manufacturing Production Process Overview

Our process ensures seamless communication, quality control, and customer satisfaction from initial inquiry through delivery.

Expert Metal Fabrication Services: Cutting, Bending & Welding

Sheet & Plate Processing:

- Cutting, Bending, and Welding are performed in-house by MWG craftsmen and women.

- State-of-the-art nesting software maximizes sheet yields and overall production efficiencies.

- Sheet processing capacities of up to 60″ x 120″ enable us to reduce material costs and keep parts’ prices low.

- Automated sheet loading and pallet changing technologies eliminate non-value-added material handling costs.

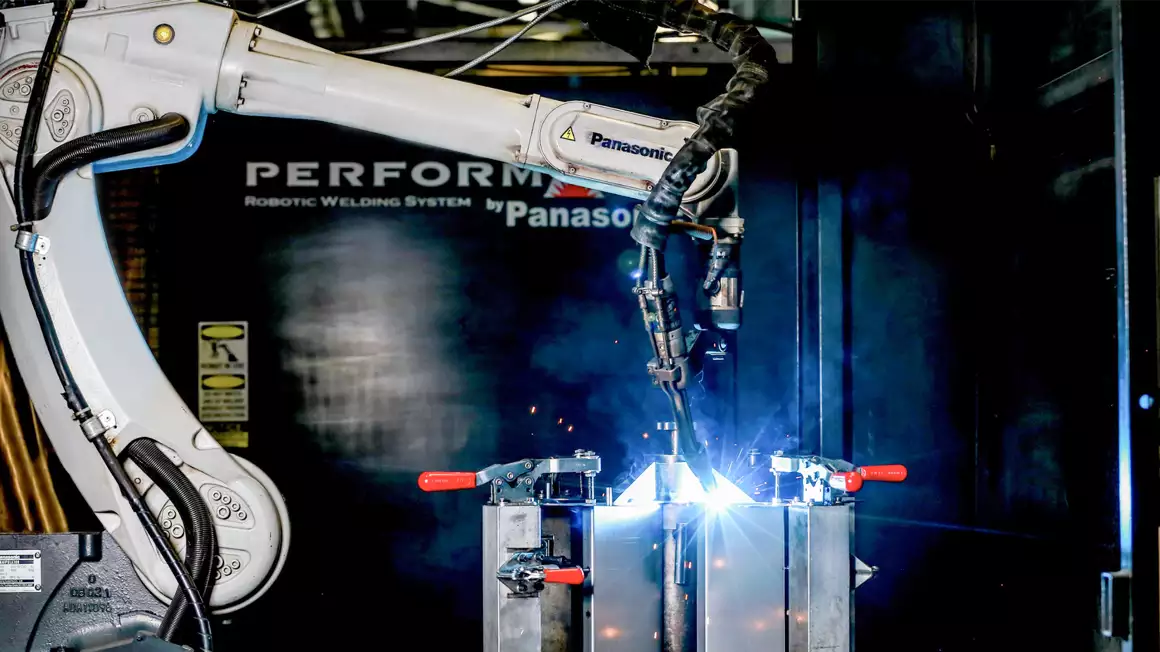

Welding (Production, MIG, TIG, Robotic):

- Our team of 60 skilled welders, supported by in-house CWIs and Weld Engineering, holds certifications that meet a wide range of industry standards, including those for oil and gas, electronics, security, military, and defense. We are committed to meeting customer needs and will obtain any required certifications we do not already have.

- Our four robotic welding cells enable us to manufacture products at a high volume.

- With cranes capable of lifting up to 40,000 pounds, our versatility enables us to create weldments of all sizes, from handheld components to those as large as shipping containers.

Complex Fabrications:

- Our team specializes in fabricating intricate designs that incorporate multiple components, diverse materials, complex geometries, tight tolerances, and sophisticated fixturing

- With over 125,000 square feet of manufacturing space, we handle large-scale projects efficiently.

Precision Machining

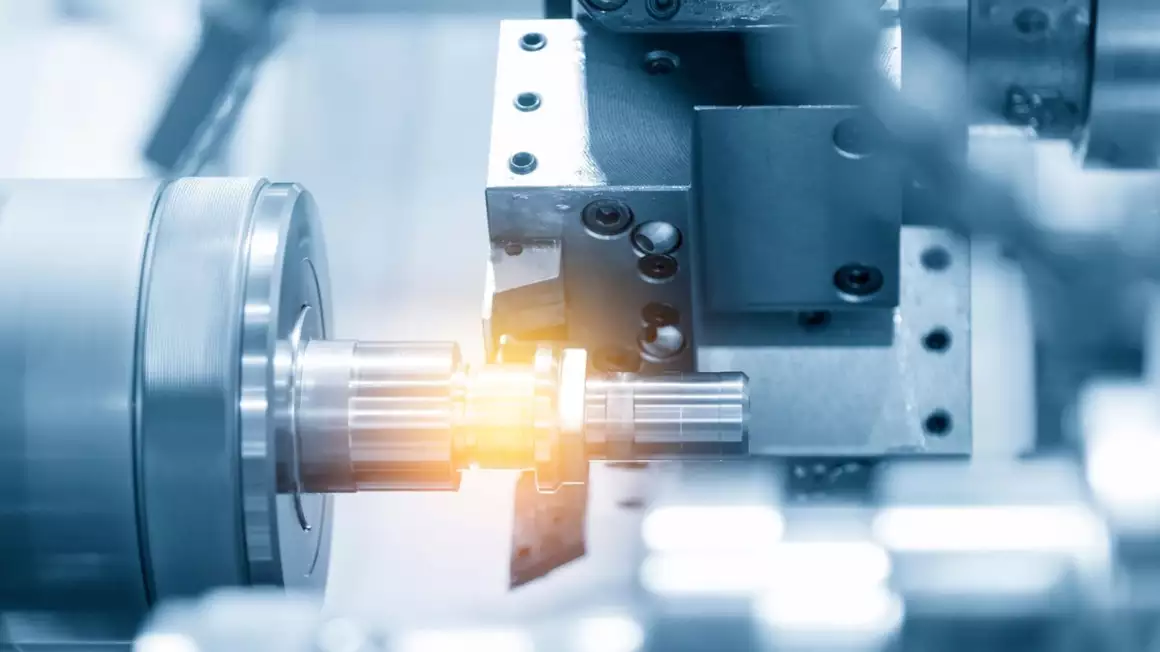

CNC Milling:

- Using the latest technology results in high-volume production at minimal cycle times.

- Our 4-axis vertical CNC machining centers eliminate the need to reposition parts during the machining cycle.

- Multiple machine options such as through-spindle coolant allow for increased speeds and feeds.

CNC Turning:

- CNC turning centers with bar-changing and bar-feeding capabilities enable operators to run multiple machines simultaneously.

- Lathe turning centers feature multi-spindle capability with live tooling, enhancing efficiencies and accuracy.

Finishing & Assembly Solutions

Finishing:

- We provide extensive manufacturing, finishing, powder coating, and assembly services in-house, giving us control of the manufacturing process from start to finish.

- If outsourcing is needed, we have a small network of local strategic partners to provide any specialized finishes. This includes plating, anodizing, heat treating, hot-dip galvanizing CARC paint, Carboline paint, and various other liquid coatings.

- Our in-house wash system utilizes a five-stage in-line pretreatment system to ensure a long-lasting durable finish.

Assembly

- Mechanical assembly, hardware kitting, custom packaging, warehousing, and distribution services are available.

Quality Assurance

ISO/CMMC/Mil Standards:

- MWG is ISO 9001:2015 Certified, ITAR Compliant, and able to ensure parts meet CMMC and Military standards.

Documentation:

- At MWG, we pride ourselves on our deep understanding of industry quality standards and documentation requirements. Our team is well-versed in adhering to stringent specifications across multiple industries including Medical Device, DoD, Oil & Gas.

Value Added Services

KAN BAN, Stocking, and Inventory Management:

- MWG strives to create value for our customers by offering many types of production models. Our inventory management programs balance just-in-time production with demand-driven stock availability, resulting in optimal inventory levels, cost reduction, and increased operational agility.

- KANBAN streamlines workflow by producing only what’s needed, reducing inventory costs, and enhancing responsiveness to demand, while improving quality control.

- Stocking programs ensure critical items are readily available to avoid stockouts, improve lead times, and enable bulk purchasing savings.

On-Staff Weld Engineers & Certified Weld Inspectors (CWI) and Project Management:

- With larger or more complex projects, an experienced project engineer will plan, coordinate, and facilitate all aspects of the project. The engineer acts as a single point of contact for the customer and is responsible for establishing timelines, production planning, and keeping our customers informed at every step.

- Our Weld Engineering and CWI teams work closely with our customers with robust welding needs and requirements. This technical expertise ensures that the products are produced to the required standards.

Shipping and Delivery:

- The Metalworking Group provides flexible shipping solutions customized to meet each customer’s unique needs. Our services include coordinating specialized trucking, arranging expedited freight, and managing shipments to multiple destinations across the U.S. and internationally.

Custom Fixtures and Tooling:

- We take pride in our in-house tooling design and production capabilities. By designing and manufacturing much of our own tooling, we lower upfront costs and ensure exceptional consistency and repeatability in every part we produce.

VAVE - Value Added Value Engineering:

- Our engineers and craftsmen design for manufacturability for optimal efficiency and cost. As we create the Standard Routings for the products we manufacture, we often look for design suggestions to reduce cost and improve manufacturability.

What’s Your Industry? We’ve Got You.

We have a very diverse operation, offering many manufacturing solutions to a wide range of customers.

- Material Handling

- Defense & Military

- Data Centers

- Medical Device

- Fitness Equipment

- Oil & Gas

- Biogas Reclaiming

- Border Security

- Autonomous Vehicle

- Industrial Equipment

- Chemical Dispensing

- Clean Energy

Contact us today to learn more about our capabilities and how we can help you achieve your manufacturing goals.

Get A QuoteWhat We Do FAQs

What manufacturing services does MWG offer?

MWG provides comprehensive metal fabrication and machining services, including sheet and plate processing, CNC milling and turning, robotic and manual welding, finishing, assembly, and quality assurance.

What industries does MWG serve?

MWG serves a diverse range of industries, including data centers, medical devices, defense, oil and gas, electronics, fitness, security, and manufacturing OEMs.

What certifications does MWG hold?

MWG is ISO 9001:2015 certified, ITAR compliant, and adheres to CMMC and military standards.

Does MWG offer value-added services?

Yes, MWG offers services such as KANBAN inventory management, custom tooling design, project management, and flexible shipping solutions.

How does MWG ensure quality in its manufacturing processes?

MWG employs certified weld inspectors, utilizes advanced equipment, and maintains rigorous quality control protocols to ensure high-quality outcomes.

Does MWG have the capability to produce extra-large parts?

Yes, MWG produces parts from the smallest bolt to large skids and frames. With over 200,000 sq ft of manufacturing space and 20,000 lbs of lifting capacity, we can produce parts of every size.